Equipments & System

Equipments

Here are 4 loading stations for 4 containers loading a time and over 5000 square store house for satisfying customers’ needs. Load, unload, partial delivery is acceptable.

Automatic conveyor loading system

Products load in the sterilized boxes (TOTE) ( 120LX 58W X 100 H cm, max 150 kg). Record the products and distributed by the dose mapping for the quantity control. The automatic conveyor and loading equipment save a lot of time and manpower.

Radiation dose measurement system

The radiation dose detection is adopted by the dosimeter form FarWest Technology. (USA), and adjusted according to the US national standers to measure the maximum and minimum by computer.

Shelf Lift/Transfer Area

Shelf Lift/Transfer Area is controlled by PLC system. Loading the boxes on the shelf and exchanging for evening the dosage.

Overhead Product Conveyor & Carrier

Overhead Product Conveyor & Carrier assembled by 3 motors and chains controlled by PLC for the irradiation procedure.

Safety detection system

Safety detection system divided into two parts. One is environment detection and the other is irradiation chamber difference detection and irradiation detection.

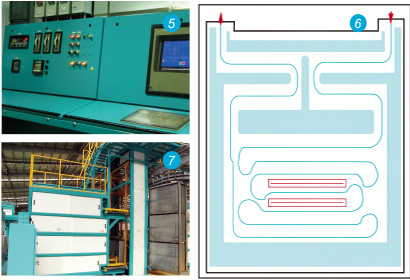

Factory and equipment patterns

1. During loading, dosimeters are placed to measure minimum and maximum dosage received throughout the cell.

2. The dose measurement system.

3. The loading station.

4. Conveyor System:The conveyor system will be controlled by a programmable controller.

5. PLC Control system

6. Gamma Cell Layout.

7. 4-Shelf Lift/Transfer Area, Overhead Product Conveyor & Carrier